Lime as part of a mortar mix

Firstly we base our case study around the following statement before looking at two types of traditional stonework that we encounter in the course of our work before going on to give a justification for the use of lime as part of a mortar mix.

“The successful repair of traditional buildings requires a thorough understanding of their construction, how they remain dry, and the mechanisms, processes and causes of decay”

|

|

|

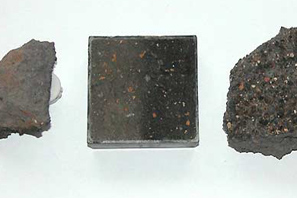

| Ashlar stonework | As taken from the Royal Cornwall Museum at Truro | |

|

|

|

| Rubble stonework | As taken from a local church from the Victorian period |

So why do we use lime as opposed to exclusively using Portland cement? Portland cement has many benefits and is widely used in the construction of modern building due to the reasons listed below:

- High compressive strength

- High modulus of elasticity

- Low porosity

- High strength

- Dense & brittle

However as previously noted, historic buildings are different in their make up which have generally stood the test of time and it can be summed up in the following statement:

“Where mortars have survived without damaging the building fabric they have the perennial qualities we should be trying to achieve. Copying old mortars leads to the use of an appropriate combination of materials”

So what are the benefits of lime?

- Most versatile binder known to man

- Live self healing material

- Accomodates seasonal movement

- Soft, porous & sacrificial

- Joints collect potentially damaging salts

- Plasters have low thermal conductivity

- Lime slurry consolidates mud mortars/plasters

There are many types of lime and finding the right mix via mortar analysis is a key part of our work. When you compare the two types of stonework featured above you can see that they are totally different and hence the need to make sure that the correct mix is found for each scenario, in fact its fair to say that no two situations are the same.

|

|

|

| Equipment used for analysis | Original bedding mortar either side of repaired mortar |

Having analysed the samples it is now as case of working out the correct type of mortar mix which suits the building fabric, the local environment and has the durability to withstand the many chemical processes that it will face like salt crystallization, cracking and water penetration.

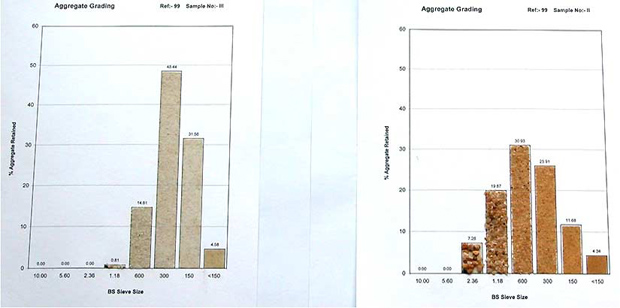

The use of grading graphs helps us to determine the correct solution.

Having worked out the correct mortar mix we then present the solutions to our clients for their approval.

The work is then carried out in a way that not only compliments the existing structure but also ensures that the building fabric should last for many years to come.